Description

MODEL : MVS-VT150, MVS-VT200

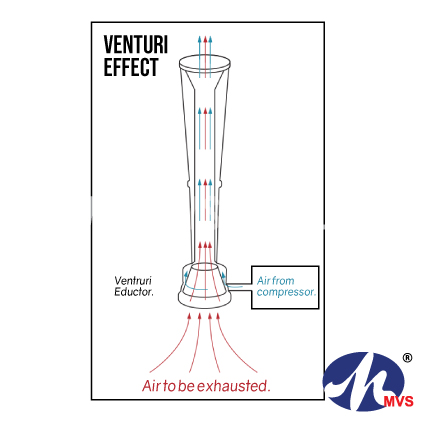

MVS Venturi Blowers provide an ideal solution for exhausting air in various industrial settings including

refineries, utility & power plants, marine shipyards, paper & pulp plants and steel mills & foundry. They are specifically designed to effectively remove potentially harmful fumes, which can be poisonous, explosive or hazardous from work areas such as in tanks, in large pipes or confined spaces.

These blowers can provide much needed ventilation for workers and equipment in high-temperature conditions. Our range of high-performance Venturi Blowers creates a safe and healthy work environment, ultimately enhancing efficiency and productivity by eliminating welding fumes,

hot air, harmful gases or smoke from your working environments. These portable and lightweight blowers allows for quick installation and removal.

FEATURES

- Single piece cast aluminum eductor inlet housing.

- Aluminum horn diffuser.

- Plastic handle.

- Quick coupling or Chicago inlet connection.

AVAILABLE MODELS

- MVS-VT150

- MVS-VT200

SPECIFICATION

-

MODEL : MVS-VT150

- HORN TOP DIAMETER : 6″/ 150mm

- OVERALL LENGTH : 520mm

- BASE DIAMETER : 165mm

- INLET : 20PM

- AIR CONSUMED AT 100 PSIG : 50 CFM

- TOTAL AIR FLOW AT 100 PSIG : 1250 CFM

MODEL : MVS-VT250

PACKING INFORMATION

- 1 unit / carton